What We Do

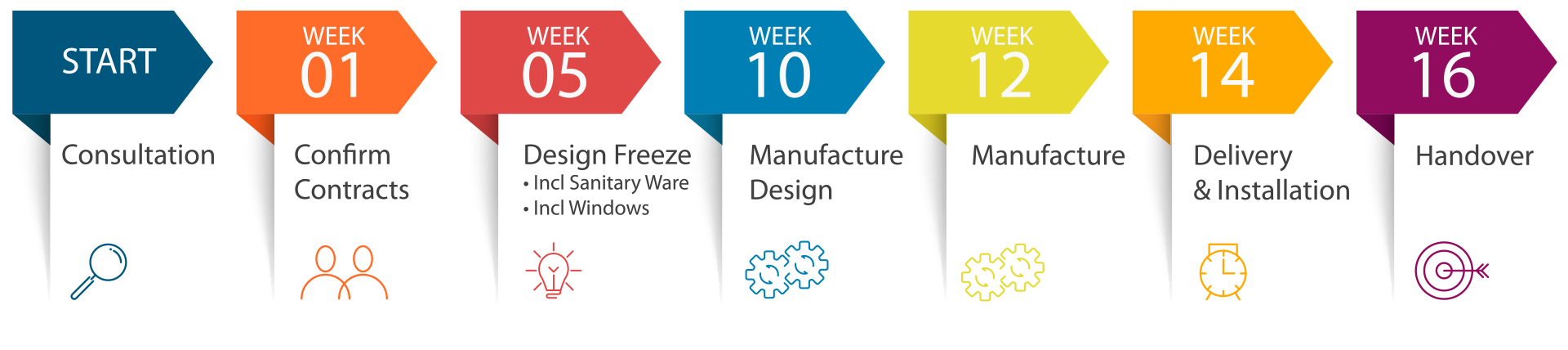

Greenstone offer clients a complete package of design, manufacture and build. In a typical project, our design team will collaborate with a clients architect or engineer to review the architectural design of a project from the context of offsite construction. This will initially lead to an accurate costing and project quotation and subsequently commence the process to design freeze.

The management and production team at Greenstone Structures are focused on a continuous innovation and improvement approach to the systems and processes used in further developing the Greenstone Structures Build System. This focus on innovation results in maximising product quality, production efficiency a, overall competitiveness for the client and profitability of the business. The deployment of a fully integrated quality management system ensures that all processes are fully recorded, reviewed and improved in an ongoing basis.

Design & Engineering

The company has a full time inhouse design team compiled of highly experienced engineering professionals with decades of experience in LGS and offsite construction. The team utilises the latest Vertex BIM (Building Information Modelling) software which produces a fully detailed 3D model including every component and element used in the manufacturing and construction process.

Manufacturing

The company has invested in the latest technology cold roll forming equipment which is CAD CAM controlled from the design office. Operations also include a CAM vertical panel saw and assembly process. A digital production management system is employed to ensure full traceability of materials, quality assurance, productivity, and product delivery.

Build

All projects have dedicated project management appointed from the concept and consultation phase. All site works are supervised ensuring preparations for the structure meet the tightest tolerances. Installation takes 48 hours for a block of 2 semi-detached units which includes full weather tight structure.